Technical Means

MACHINERY

- Pyrolytic oven for burning parts without damaging the magnetic core

- Drying oven for gas recovery

- Coil manufacturing machinery: Press, metal forming machine, tedder, wrapping machine, etc.

- Strapping lathe

- Equipment for lifting and handling heavy parts (cranes, forklifts, etc.)

- Induction welding equipment

- Oxyhydrogen welding equipment

- Deposits for impregnation by dipping

- Test benches with and without load

- Dynamic accuracy balancers

- Magnetizers up to 30,000 A/P

- Machining Centers

- Own shipping

- Winding checkers through non-destructive testing.

- And a full range of instruments for on-site diagnosis.

MEASURING EQUIPMENT

- Dielectric rigidity equipment up to 25 kV

- Shockwave equipment to detect short-circuits of up to 30 kV between turns.

- Insulation resistance measuring equipment

- Resistance (Ohms) measuring equipment

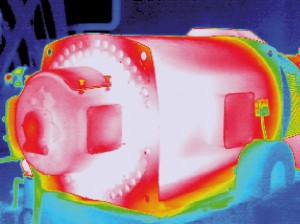

- Equipment to detect hot spots in magnetic core

- tg δ measuring equipment

- Partial discharge equipment

- Laser aligner

- Vibration and noise analyzing equipment

OUTSIDE ASSISTANCE EQUIPMENT

- Outside insulation measuring equipment

- tg δ measuring equipment

- Partial discharge equipment

- Shockwave unit

- Vibration and noise analyzer

- Laser alignment unit

- Thermographic chamber

- Flatness measuring equipment

METICULOUS PROCEDURES

A detailed report is sent with each repair or diagnosis about the status of the motor or drive when it was received and when it is sent out. Indicating the detected malfunctions or anomalies, the actions carried out and the materials used to repair it.

The history on the items repaired or diagnosed makes it possible to do a personalized and continuous follow-up on them.

The repairs are done under standards ISO 9001, ISO 14001 and OHSAS 18001